3 min read

How SEM and BIB Milling Are Transforming Battery Manufacturing

Sep 10, 2025 3:05:40 PM

The future of energy storage depends on our ability to manufacture better batteries. But achieving this goal becomes more difficult as electrode materials advance and cell chemistries become more complex.

Many of the most common (and costly) problems in battery performance, such as yield loss, capacity fade, or safety failures, stem from physical defects at the micro or nanoscale. These include cracking, particle agglomeration, inconsistent coatings, or delamination. The challenge is: how do you reliably detect and analyze these issues, especially at scale?

That’s where broad ion beam (BIB) milling and scanning electron microscopy (SEM) come in. A new whitepaper from Hitachi High-Tech Europe outlines a comprehensive workflow that combines ultra-precise cross-sectioning with automated SEM analysis and AI-driven image interpretation. The result? A powerful toolkit for improving quality, safety, and performance across the battery development lifecycle.

You can read the full whitepaper here.

In this article, we unpack the key takeaways through a Q&A format designed to help battery scientists understand what’s possible with today’s analysis tools. And how they can apply them in their own labs or manufacturing lines.

Let’s start with the first question.

Why is structural analysis critical in battery development and production?

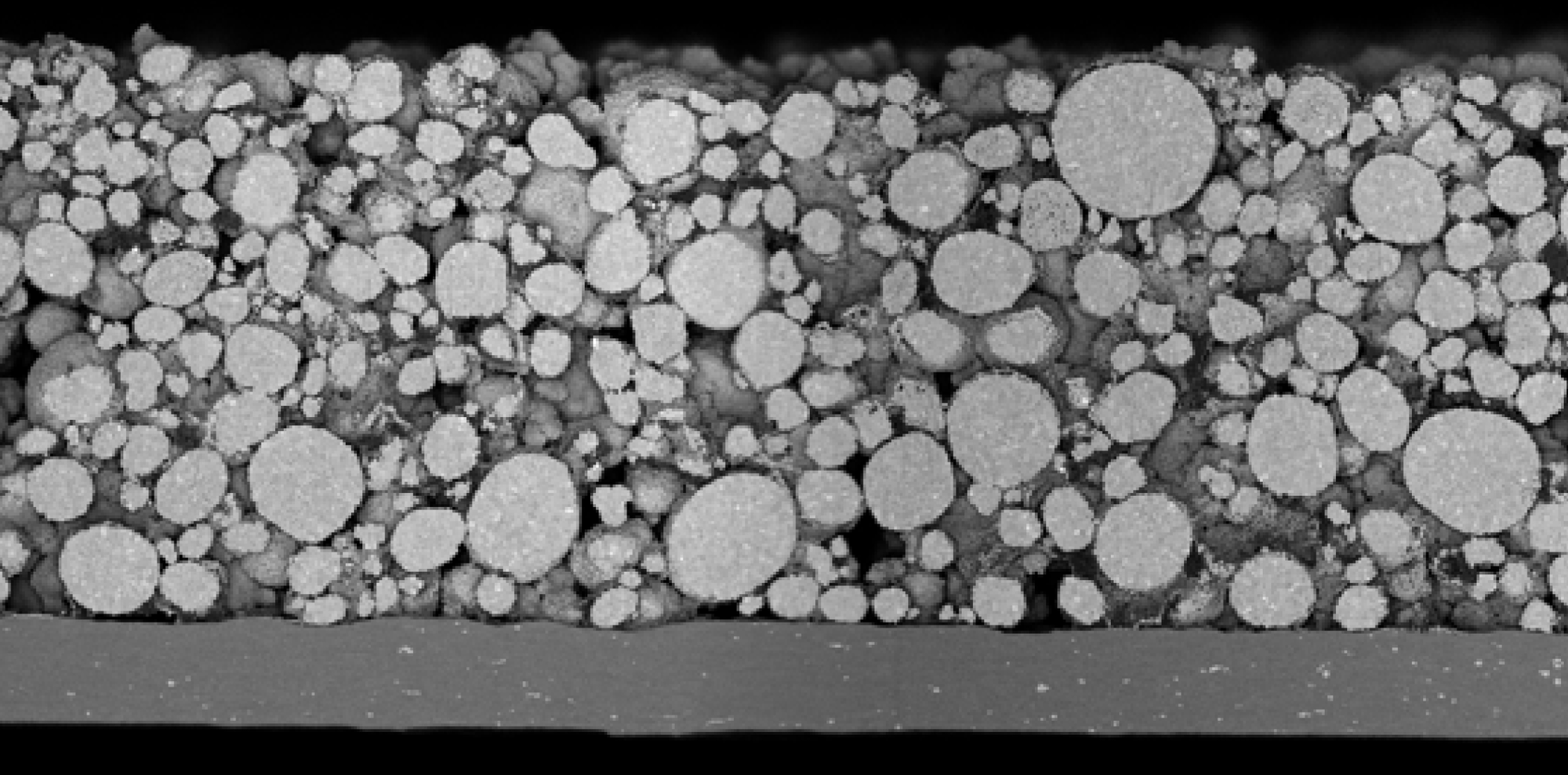

So much of a battery’s performance is determined by structure. Whether it’s the thickness of the electrode coating, the porosity of a separator, or the distribution of binder in a cathode, microscopic variations can lead to major differences in cycle life, energy density, and safety. Cross-sectional analysis helps visualize and quantify these hidden features, making it an indispensable tool for R&D, process control, and failure analysis.

What common manufacturing issues can SEM and BIB milling help address?

This workflow can reveal a range of issues, such as:

- Non-uniform coatings or thickness variation across foil width

- Agglomeration of particles or poor binder distribution

- Microcracks in polycrystalline cathode materials

- Delamination from the current collector or separator

- Pore collapse or excessive tortuosity affecting ion transport

- Phase segregation in active materials like NMC or LMNO

These problems may originate during coating, drying, calendaring, or even post-cycling.

How does BIB milling differ from traditional prep methods like cutting or polishing?

Traditional methods like cutting and polishing introduce mechanical artefacts—such as smearing, delamination, or displacement of particles—which distort the sample and make imaging unreliable. Broad ion beam milling uses a masked argon ion beam to mill cross-sections with minimal damage and high uniformity. It’s especially useful for hard-soft material combinations and can handle heat-sensitive components without thermal artefacts.

How large are the cross-sections that BIB can produce?

Hitachi’s ArBlade 5000 system can reliably produce cross-sections ranging from 1 mm to 40 mm wide, while maintaining structural fidelity. This is a game-changer for statistical analysis, because it allows users to observe tens of thousands of particles in a single section, something that’s nearly impossible with narrower sections from FIB tools.

Once the sample is prepared, how does SEM fit into the workflow?

SEM provides high-resolution imaging of the cross-section. Hitachi’s SEM systems use secondary electron imaging for morphology, backscatter electron imaging for contrast and composition, and EDS for elemental analysis. Different detectors and beam energies can be used to optimize for beam-sensitive materials like separator foils or polymeric binders.

What role does automation play in SEM image acquisition?

Hitachi SEMs can be fully automated using EM Flow Creator, a no-code platform that allows operators to create imaging routines without writing scripts. This enables batch image acquisition at multiple magnifications across a wide cross-section, which saves time and improves consistency. Automation is essential when analyzing large datasets, such as comparing different regions of an electrode or evaluating samples from different cells.

Can AI really help interpret SEM images at scale?

Yes. Deep-learning algorithms can now classify and measure structural features such as particle size, crack length, porosity, and binder distribution with high accuracy. This shifts SEM from a purely visual tool to a quantitative engine, capable of delivering actionable data in minutes. It also helps detect low-frequency or subtle defects that human reviewers might miss.

Are these techniques only applicable to lithium-ion batteries?

No—they’re applicable to a wide range of chemistries, including:

- Nickel manganese cobalt oxide (NMC)

- Lithium iron phosphate (LFP)

- Lithium manganese nickel oxide (LMNO)

- Sodium ion batteries (SIB)

- All solid state batteries (ASSB)

Each chemistry presents unique structural challenges, and BIB + SEM can be tailored to address them through optimized milling and imaging parameters.

How does this workflow help with post-cycling or failure analysis?

After formation and cycling, batteries often degrade due to structural changes: SEI layer breakdown, lithium plating, crack propagation, or loss of contact between particles. These changes can be subtle, but with BIB + SEM and inert handling workflows, researchers are able to preserve oxidation-sensitive features like the SEI layer and detect changes that would otherwise be missed.

What’s the real business impact for manufacturers?

With BIB + SEM, manufacturers can:

- Reduce scrap and rework by catching defects early

- Shorten development cycles with faster feedback

- Improve product consistency and customer satisfaction

- Gain confidence in scaling new materials or processes

It’s a quality-control toolkit that drives bottom-line performance.

Conclusion

From lab bench to factory floor, BIB milling and SEM are reshaping how battery R&D approaches quality and safety. These tools don’t just reveal problems, they help you prevent them.

With advanced automation, deep learning, and ultra-wide cross-sectioning, the combination of BIB and SEM systems empowers teams to move faster, analyze smarter, and deliver batteries that perform better.