Combine SEM and BIB milling tobetter understand LiB materials

Learn how to enhance your LiB materials research by combiningSEM and BIB milling for deeper insights, high-qualitycross-sections, and improved battery performance.

Download the whitepaper

1 min read

May 22, 2025 5:02:28 PM

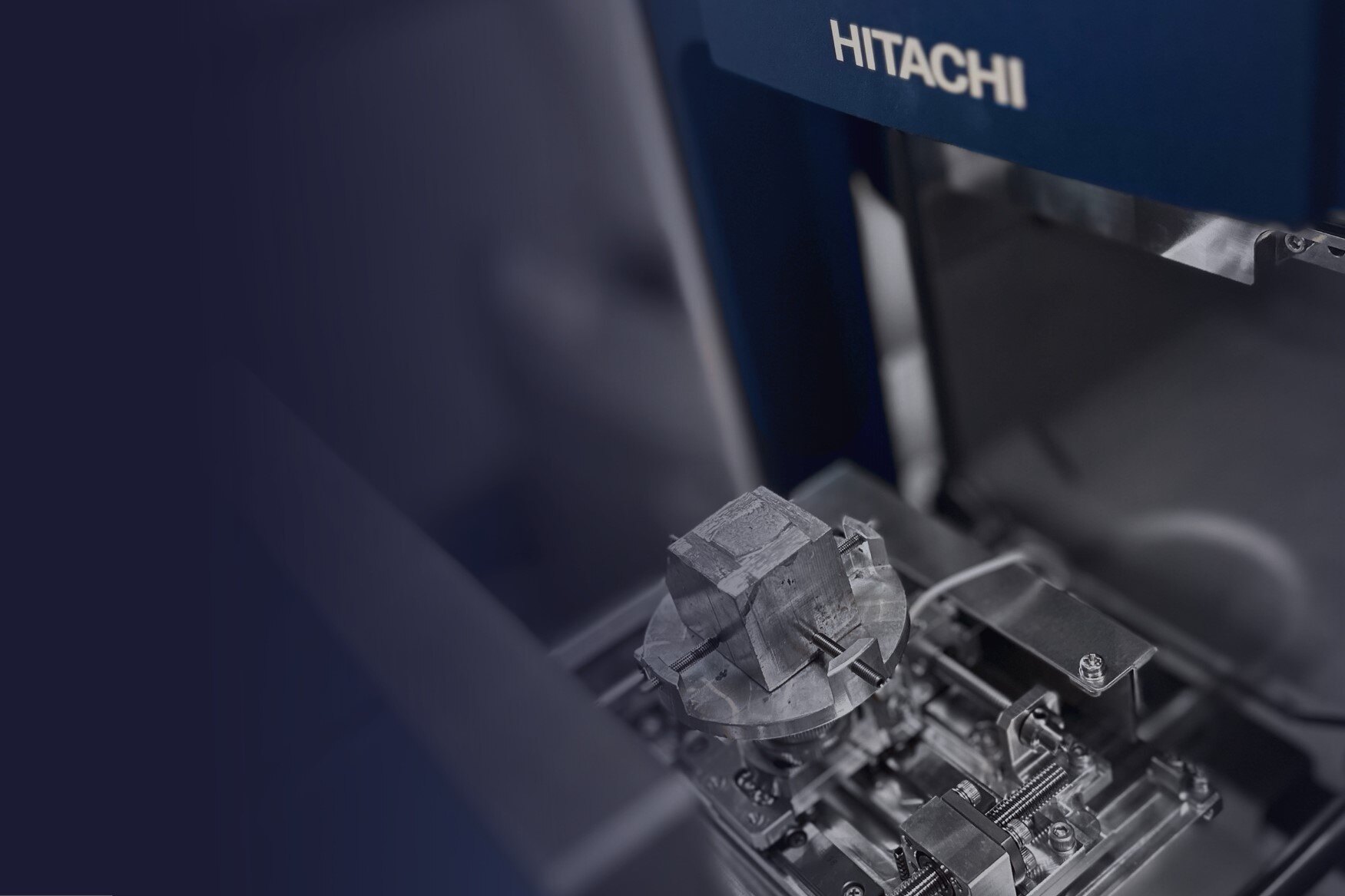

A meaningful SEM analysis requires high-quality specimen preparation. Conventional mechanical sample preparation techniques for artefact-free surfaces or cross-sections, such as mechanical grinding and polishing, fracturing, or cutting by scissors or knifes, etc., can deliver usable results on some specimens. However, they can also fail, especially when it comes to composites and layered structures with different hardness, brittle materials, and so forth.

This facilitates the need for better techniques, one of which being the powerful Broad Ion Beam Milling method which will be explored in this article.

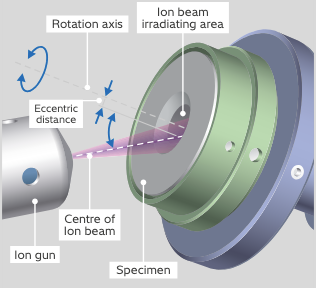

Broad Ion Beam (BIB) milling is a complementary SEM sample preparation technique that uses on a microscopic scale accelerated Argon ions to sputter material from a specimen surface, comparable to the macroscopic sand blasting for the cleaning of parts. As this does not apply any mechanical force that could cause material deformation or displacement, the outputs are clean surfaces on a millimetre-order revealing the “true” nature of the specimen, thus being ideally suited for SEM imaging and analysis.

Learn how to enhance your LiB materials research by combiningSEM and BIB milling for deeper insights, high-qualitycross-sections, and improved battery performance.

Download the whitepaper

In unserem On-Demand-Webinar mit Oxford Instruments erfanhren Sie, wie Sie die Leistung eines TTM/EDS-Energiesystems (Table Top energiedispersive Spektroskopie) maximieren können.

Download the whitepaper