SU3800 / SU3900 Family

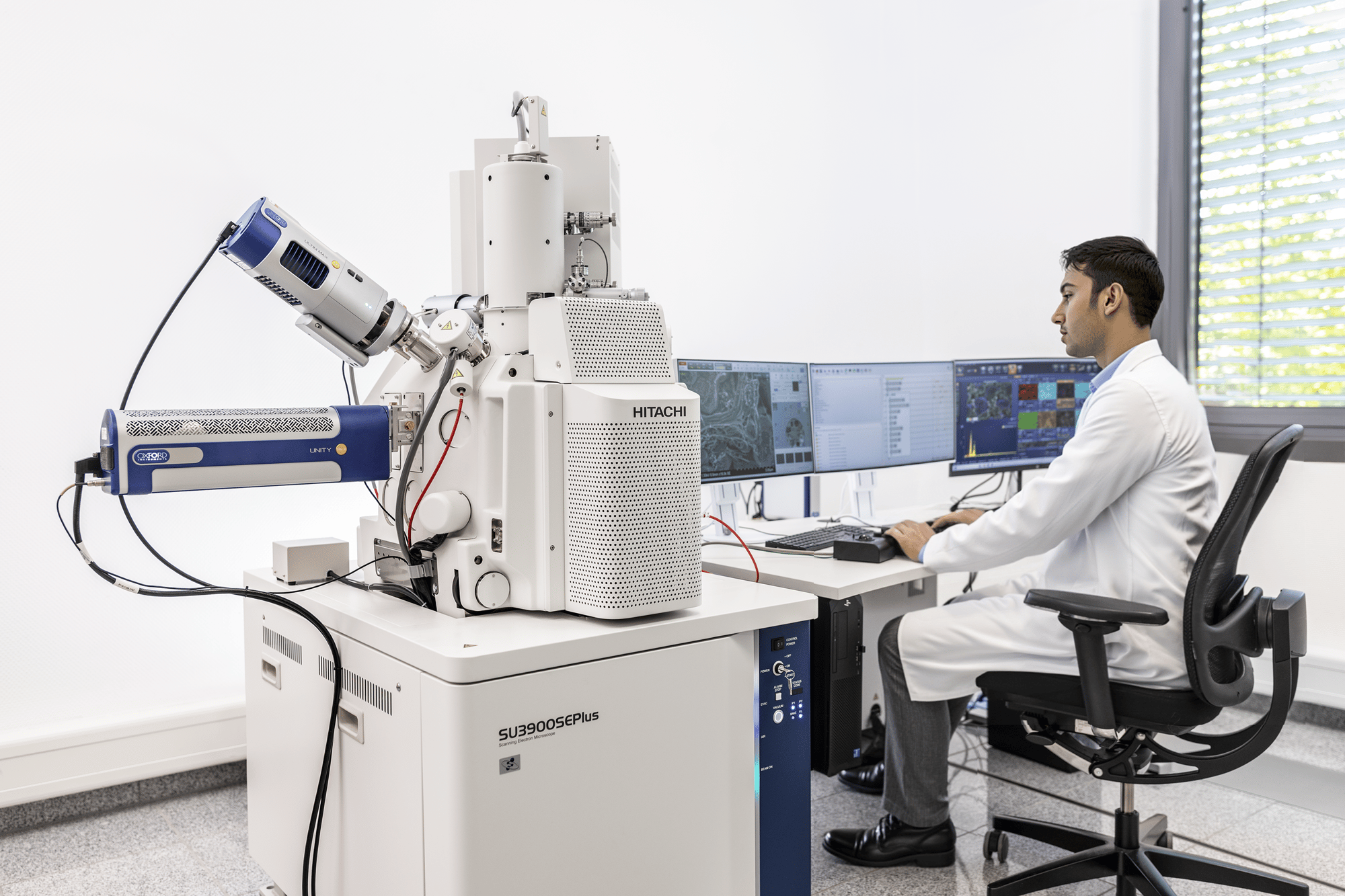

SU3800/3900 Universal Scanning Electron Microscope Family

Powerful, versatile VP-SEMs with a choice of electron source and specimen chamber size. Designed for performance, large-sample handling, and user-friendly automation imaging needs in academia and industry.

- Accommodate and inspect large, heavy samples with ease

- Flexible, robust sample stages for any application

- Wide-area observation with SEM MAP technology

- Automation for consistent, high-quality results

- Designed for a variety of applications

What is the SU3800/3900 family?

The Hitachi SU3800/3900 family is a modular, user-friendly scanning electron microscope platform with variable chamber pressure capabilities. This modular design means you can configure the best instrument for your application:

Choose your Electron Source

Tungsten Hairpin Filament

Cost-effective option for low to medium-demand imaging requirements

The SU3800T or SU3900T

Schottky Field Emitter

High-performance option boosted by beam deceleration technology, for high-resolution imaging

The SU3800SE or SU3900SE

Choose your sample chamber size

Standard-size

Up to 200mm Ø, 80mm (H), 2kg sample weight

The SU3800T or SU3800SE

Jumbo-size

Up to 300mm Ø, 130mm (H), 5kg sample weight

The SU3900T or SU3900SE

Why choose the SU3800/3900 platform?

The Hitachi SU3800T/3900T and SU3800SE/3900SE scanning electron microscopes are designed to tackle the challenges of modern microscopy - whether you’re working in academic research, industrial labs, or quality control environments. These instruments offer the perfect balance between versatility, high performance and ease of use, letting you focus on what matters: getting reliable, accurate results every time.

Both base models are equipped to handle a wide range of sample sizes and types, from small specimens to large, heavy industrial components. With advanced automation features and powerful navigation tools, the instruments in the SU3800/3900 series help you streamline your workflows, improve productivity, and achieve consistent, high-quality results.

Features and benefits

-

Accommodate and inspect large, heavy samples with ease

Whether you’re working with large industrial materials or smaller research samples, the SU3800 and SU3900 specimen chambers with their eucentric stages have you covered.

SU3800: Accommodates samples up to 200 mm in diameter, 80 mm in height, and 2 kg in mass.

SU3900: Designed for extra-large samples, you can load specimens up to 300 mm in diameter, 130 mm in height, and 5 kg in mass. Ideal for imaging large-scale industrial components.

With these spacious chambers, you can skip the time-consuming step of cutting or modifying large samples down to smaller sizes, allowing for faster sample preparation.

-

Flexible, robust sample stages for any application

Both models feature advanced eucentric motorized stages with 5 axes (X, Y, Z, tilt, and rotation) for precise positioning. Stages can be fully retracted from the specimen chamber for easy, collision-risk-free positioning of even large and heavy specimens.

SU3800: Sample stage moves across 0–100 mm (X-axis) and 0–50 mm (Y-axis), with a Z-axis range of 5–65 mm. At maximum, a disk with 130mm diameter can be fully observed.

SU3900: The larger SU3900 stage provides greater flexibility, with ranges of 0–150 mm (X-axis), 0–150 mm (Y-axis), and 5–85 mm (Z-axis), making it ideal for large or irregularly shaped samples. In total, a 229 mm diameter region can be imaged.

-

Wide-area observation with SEM MAP technology

Both the SU3800 and SU3900 are equipped with SEM MAP, a powerful tool for navigating large specimens.

SEM MAP displays a zoomable optical color photo, matching the maximum SEM-observable region of the specimen (130mm Ø / 229mm Ø). The photo is acquired automatically during chamber evacuation, allowing you to center any point of interest under the electron beam with just a mouse click. SEM overviews can be locally patched instantly for enhanced navigation accuracy.

SEM MAP also works with SE and EDS detectors. The tool gives you a clear understanding of whether an observed specimen location is properly oriented towards the desired detector for the best signal collection. Total clarity is achieved by having the SEM MAP display rotation-linked to the actual SEM or stage rotation settings.

-

Automation for consistent, high-quality results

Hitachi’s automation and support features are designed to take the stress out of operating an SEM, no matter your experience level.

A user-definable operating condition library loads an entire working environment (optics setting, vacuum mode, detector settings, stage conditions), instantly setting the desired conditions for completing a specific task.

Automated functions for focus, brightness, contrast, and more allow you to start imaging immediately after sample loading.

The Schottky field-emission column version comes with fast and fully automated optics alignment, executable on the spot for typical real-world specimens.

For the tungsten-hairpin filament source, Intelligent Filament Technology (IFT) dynamically optimizes filament heating and monitors filament conditions in real-time, ensuring optimal performance and high filament lifetime.

Multi Zigzag functionality automatically acquires and stitches together multiple high-magnification images, giving you a detailed, wide-area view of your sample.

Automated workflows mean less manual adjustment and more time for data collection. EM-Flow Creator lets you define fully automated workflows for even complex imaging tasks, without coding experience.

-

Designed for a variety of applications

From academic research in biology and nanotechnology to industrial applications like quality control in automotive and materials science, the SU3800 and SU3900 are ideal for a range of use cases.

Optional accessories like heating/cooling/tensile stages, analytical instrumentation, or a STEM holder expand the range of applications, enabling in-situ observations and dynamic sample analyses.

Applications gallery

Fracture surface of iron wire

5.00kV x9.00k SE

Stainless steel SUS316

30.00kV x50.0k BSE

Printed circuit board

0.50kV x12.00k SE

Cross section of layered ceramic capacitor

2.00kV x5.00k BSE

Zinc oxide particles

3.00kV x70.0k SE

High-entropy carbide film

1.50kV-D x50.0k BSE

Lithium-ion battery cathode material

2.00kV x3.00k BSE

Lithium-ion battery anode material

0.20kV-D x10.0k BSE

Specifications

| Tungsten hairpin | Schottky FE | |||

|---|---|---|---|---|

| SU3800T | SU3900T | SU3800SE | SU3900SE | |

| Electron source | Tungsten hairpin | Tungsten hairpin | Schottky FE | Schottky FE |

| Accelerating voltage | 0.3 - 30kV | 0.3 - 30kV | 0.5 - 30kV | 0.5 - 30kV |

| Landing voltage (beam deceleration) | na | na | 0.1 - 2.0kV | 0.1 - 2.0kV |

| Secondary Electron image resolution | 3.0nm @ 30kV 15nm @ 1kV |

3.0nm @ 30kV 15nm @ 1kV |

0.9nm @ 30kV 2.5nm @ 1kV 1.6nm @ 1kV (decel) |

0.9nm @ 30kV 2.5nm @ 1kV 1.6nm @ 1kV (decel) |

| Eucentric Specimen stage | X: 0-100mm Y: 0-50mm Z: 5-65mm T: -20° to +90° R: 360° |

X: 0-150mm Y: 0-150mm Z: 5-85mm T: -20° to +90° R: 360° |

X: 0-100mm Y: 0-50mm Z: 3-65mm T: -20° to +90° R: 360° |

X: 0-150mm Y: 0-150mm Z: 3-85mm T: -20° to +90° R: 360° |

| Maximum mountable specimen diameter | 200mm diameter | 300mm diameter | 200mm diameter | 300mm diameter |

| Maximum observable specimen diameter SEM and Navigation Cam | 130mm | 229mm | 130mm | 129mm |

| Maximum specimen height with all stage axes active | 80mm | 130mm | 80mm | 130mm |

| Maximum specimen mass | 2kg | 5kg (all stage axes usable when using proper specimen holder) | 2kg | 5kg (all stage axes usable when using proper specimen holder) |

Contact us

If you would like help choosing the best SEM for your needs, or if you’re looking for advice on how to optimise your microscopy, our experts are ready to assist. Contact us today to learn how the Hitachi SU3800/3900 family can enhance your lab’s capabilities.